OK Play began its journey by manufacturing of plastic molded toys, fun stations, playground equipment and children’s furniture in India and has graduated to become the market leader in manufacturing of plastic components for automotive and industrial use & Electric Vehicles on the three wheeled platform.

The manufacturing and sale of plastic components for the automotive industry is done through OK Play India Ltd. and OK Play Auto Pvt. Ltd., a wholly owned subsidiary of OK Play India Ltd.

OK Play Group was established in 1991 and is listed on the Bombay Stock Exchange since 1994.

OK Play is a group company and operates in three segments – Toys, Auto Components and Electric Vehicles under separate subsidiary entities.

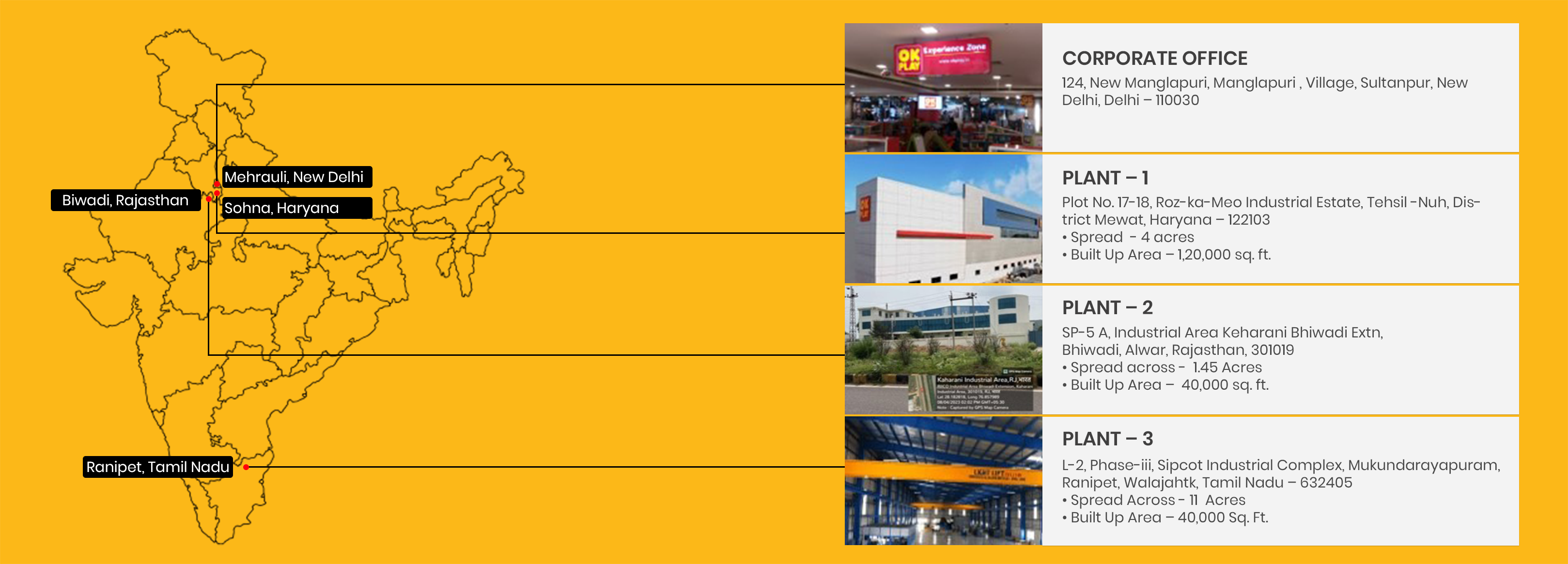

Headquartered in North India, New Delhi, OK Play Auto is the market leader in the country in the field of plastic fuel tanks and other plastic components for the commercial vehicles, Passenger vehicles, Tractor and Construction equipment industries.

OK Play Auto was the first company in the country to develop and manufacture a plastic fuel tank for M&HCV sector and is the largest supplier of plastic fuel tanks in ASIA to the M&HCVs sector, supplying over 2,50,000 fuel tanks annually.

OK Play Auto manufactures a range of plastic fuel tanks, urea tanks, water tanks, hydraulic tanks, plastic bus seats, fenders, consoles, canopy’s, air intake system’s etc for the commercial vehicles, passenger vehicles, tractor and construction equipment industries.

First domestic company to receive E-Certification for plastic fuel tanks in India

Has grown at CAGR of 25% over the last 5 years, with consistent EBITDA margins in the range of 20% - 25%

Majority market share source supplier to two out of the three largest players in the M/HCVs sector – Ashok Leyland and VE Commercial Vehicles.

At OK Play Auto Pvt Ltd, we envision a future where our innovative plastic-molded automotive parts play a pivotal role in shaping the driving experience of tomorrow. Our vision is to be a global leader, driving the automotive industry forward through cutting-edge technology, sustainable practices, and unparalleled commitment to excellence.

Technological Leadership: Embrace and lead technological advancements in plastic molding to continually enhance the performance, safety, and efficiency of automotive components. We aim to be at the forefront of transformative technologies that redefine industry standards.

Global Impact: Extend our reach globally, becoming the supplier of choice for automotive manufacturers around the world. By consistently delivering superior products, we aim to be recognized as an influential force in the evolution of automotive design and functionality.

Sustainability Pioneers: Be trailblazers in sustainable manufacturing practices. Our vision includes the widespread adoption of eco-friendly materials, energy-efficient processes, and the establishment of a circular economy within the automotive supply chain. We strive to be a model of environmental stewardship.

Read more...

At OK Play Auto Pvt Ltd, we are dedicated to being the premier provider of high-quality plastic-molded automotive parts, driving innovation, sustainability, and excellence in every product we create. Our mission is to empower the automotive industry with precision-engineered solutions that enhance performance, safety, and efficiency.

Precision Engineering: Employing state-of-the-art technology and industry-leading expertise, we strive for perfection in the design and manufacturing of plastic-molded automotive components. Our commitment to precision ensures that every part meets or exceeds the stringent standards set by the automotive sector.

Innovation: Innovation: We embrace a culture of continuous innovation, pushing the boundaries of what is possible in plastic molding technology. By staying at the forefront of advancements, we provide our clients with cutting-edge solutions that contribute to the advancement of automotive design and functionality.

Sustainability: Recognizing the environmental impact of plastic manufacturing, we are dedicated to sustainable practices. Our mission is to minimize our carbon footprint by investing in eco-friendly materials, processes, and recycling initiatives. We are committed to promoting a circular economy in the automotive industry.

Read more...

“In our pursuit of industry leadership, innovation is our driving force. We always channel our collective energy into pushing the boundaries of what's possible in plastic moulding technology. Our Research and Development efforts are the cornerstone of our future success. We, as a team, embrace creativity, share ideas, and explore new frontiers together. Together, we have always been able to position ourselves at the forefront of technological advancements and aim to always maintain our competitive edge ”

“Our people are the heart and soul of the company. Let's take a moment to appreciate the hard work and dedication each of them brings to the table. In the fast-paced world of plastic automotive components, it's crucial that we also prioritize well-being. We ensure that our work environment remains supportive, collaborative, and conducive to both professional and personal growth. Employee contributions are valued, and together, as a family, we continue to achieve great things”

“With a deep commitment to environmental responsibility, We always intensify our efforts to embed sustainability in every aspect of our operations. From material sourcing to production processes, we explore and implement eco-friendly solutions. Our vision is not only to meet current environmental standards but to surpass them, setting new benchmarks for sustainable manufacturing in the automotive component sector. Our dedication to these initiatives will not only shape the future of our company but contribute positively to our planet”

“As we navigate the dynamic landscape of the plastic automotive component industry, we always try to reaffirm our commitment to quality assurance. Our success is built on the trust our clients place in the precision and reliability of our products. Each team member plays a crucial role in upholding these standards. We collaborate closely across departments, embracing a culture of continuous improvement to ensure that every component leaving our facilities is a testament to our unwavering dedication to excellence ”